Vacuum-operated sanding/shot-peening cabins series "V"

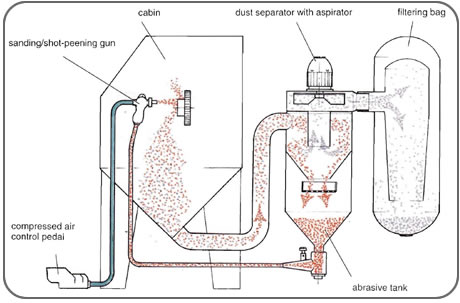

The series "V" concerns the machines making the abrasive throw through a "vacuum-operated" or "suction" system.

This series covers three standard models featured by the enlarged dimensions of the working area. All models arrange a centrifugal dust separator for the continuous recovery and restore of the abrasive. The sanding/shot-peening machines FINIMAC are manufactured complying with the up-to-dated technics and the use of the best components and materials as to get a product of:

• high quality

• long life

• large versatility

They are allowed to work with abrasives of any kind, such as:

• glass beads

• corundums and sands

• plastic granules

• vegetable granules

• metallic grits

Painting by epoxy paints -furnace baked- really wear-proof.

The "vacuum-operated" or "suction" machines carry-out the abrasive throw by means of a special gun fed by two different pipings. The former is controlled by a pedal and fed by compressed air: by a duly shaped injector it provides an air throw through the gun. The other piping is connected to the abrasive collecting tank. The compressed air throw produces -inside the gun- a vacuum sucking the abrasive through the pipe connected to the tank. Once the abrasive reaches the gun, it is thrown through the nozzle in tungsten carbide.

The gun can be easily moved, in order to position the throw towards the piece to be treated. The outcome of the treatments depends on various elements, such as:

• the pressure of the compressed air

• the type of abrasive

• the time of treatment for unit of surface |

|

The surface treatments that can be carried-out are:

• removing of polluted matters

• fettling

• hardening shot-peening

• deoxidation

• glazing for aesthetical purpose

• paint removing

• preparation of surfaces for anchoring of metals, paints, rubbers, etc.

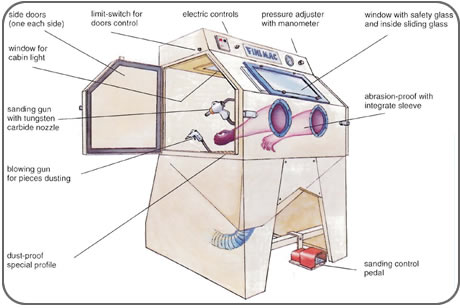

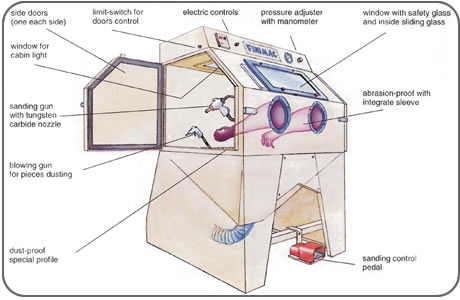

The machines of this series are mainly composed of:

• treatment cabin

• centrifugal dust-separator for the continuous restore of the abrasive in order to remove the working residuals

• double wall filtering bag for the dust-exhaustion of the air delivered in the environment. The bag can be replaced by filters of differenty type (see the relevant catalogue).

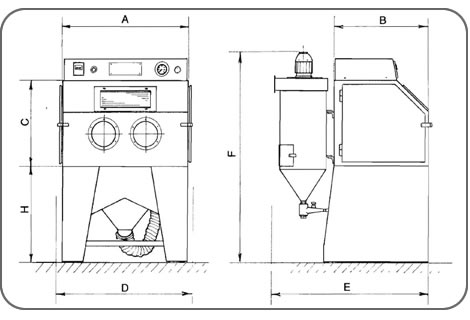

TECHNICAL FEATURES

Model

|

VO |

V1 |

V2 |

V3 |

Sizes of the working area

AxBxC mm |

700x500x500 |

900x600x600 |

1100x850x750 |

1500x1200x900 |

Height of the working surface H

mm |

850 |

850 |

850 |

850 |

Overall dimensions

DxExF

mm |

750x950x1550 |

980x1050x1650 |

1180x1300x1760 |

1580x1650x1910 |

Weights

Kg |

190 |

200 |

285 |

430 |

Compressed air consumption

a 6 bar lt/1' ' |

650 |

650 |

650 |

650 |

Aspirator power

HP |

0,75 |

0,75 |

0,75 |

0,75 |

Electric energy absorption

Kw |

0,80 |

0,80 |

0,80 |

0,80 |

Filtering surface

mq |

2,5 |

2,5 |

2,5 |

2,5 |

On request, these machines can be supplied with the following accessories:

- manual rotary table

- carriage with manual rotary table

- inside and outside roller-way

- automatic rotary table with swinging gun holding arm

- rotary drum for automatic treatment of findings

- sleeve dusting filter

- self-cleaning cartridge dusting filter

Exemples of vacuum-operated machines

Shot-peening machine with three Shot-peening machine with three

working positions |

Inside view of cabinet with Inside view of cabinet with

three working

positions |

Shot-peening cabinet with inside Shot-peening cabinet with inside

and outside roller-way |

Manual sanding cabinet supplied Manual sanding cabinet supplied

with automatic rotary basket |

|

|